LAB HOMEWORK

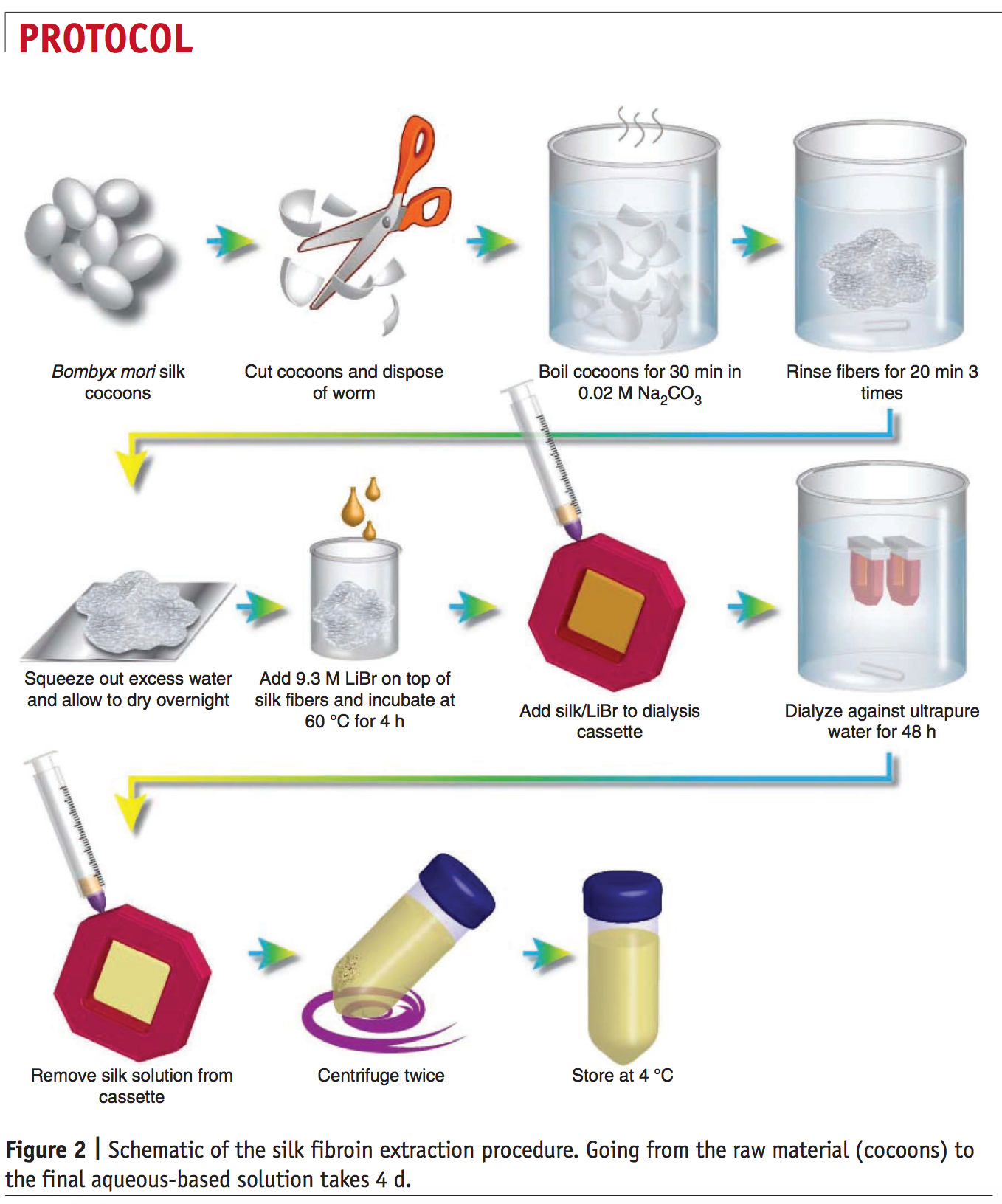

1. Regeneration of silk fibroin into an aqueous suspension

***SUPER ESSENTIAL PDF*** :: Materials fabrication from Bombyx mori silk fibroin

(Rockwood et al. Nature Protocols)

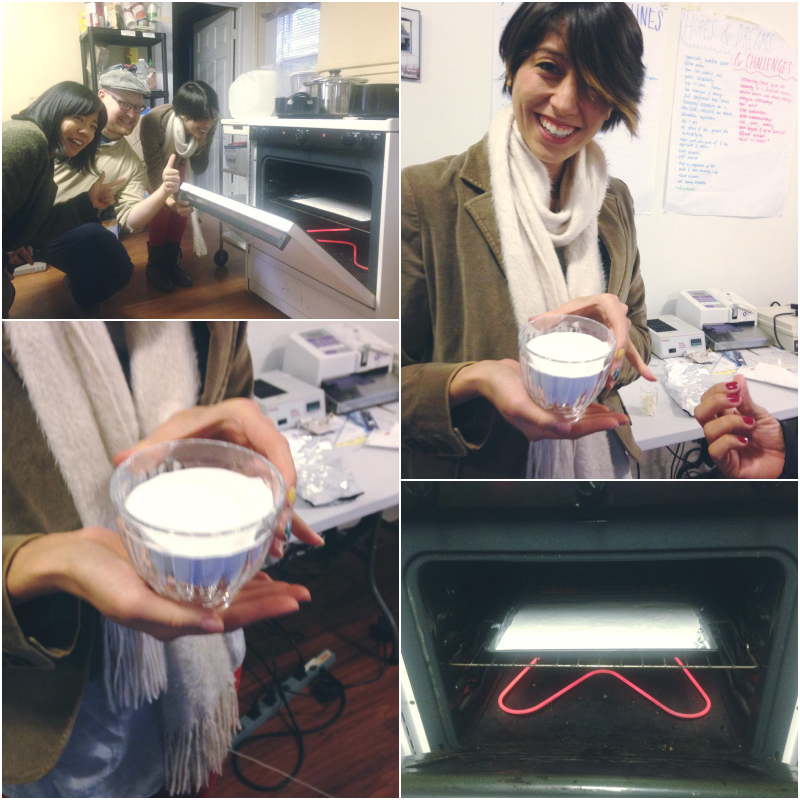

CHOPPING UP COCOONS

BAKING BAKING SODA @400 F YIELDS WASHING SODA (NA2CO3) OR SODIUM CARBONATE.

https://naturesnurtureblog.com/ttt-turn-baking-soda-into-washing-soda/

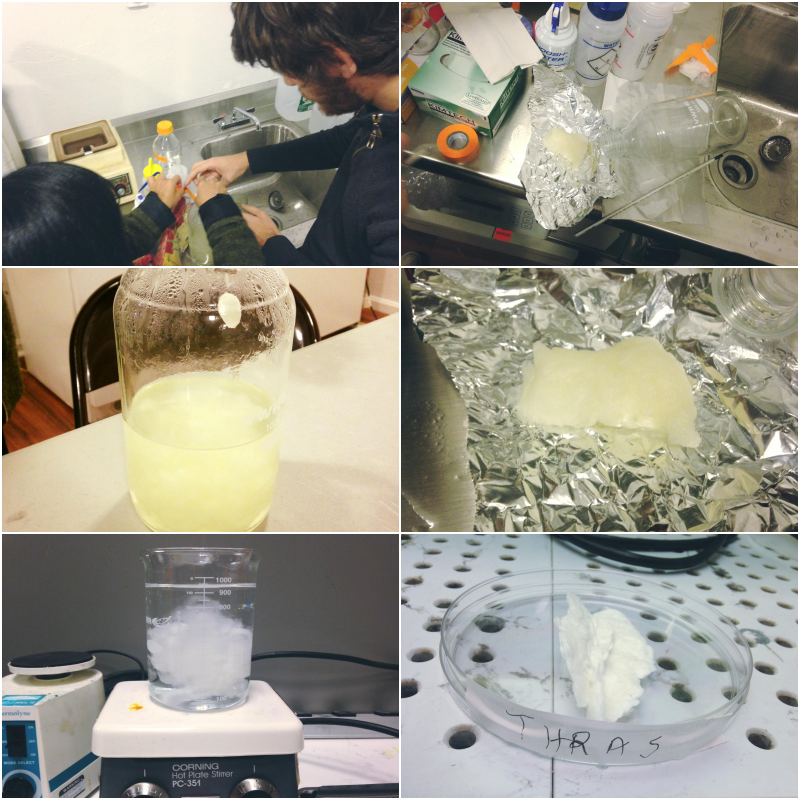

BOILING COCOONS FOR 30MIN IN WASHING SODA OR SODIUM CARBONATE AND 1 L ULTRAPURE WATER.

RINSING IN ULTRAPURE WATER FOR 20MIN, 3 TIMES, USING MAGNETIC STIR PLATE. THIS IS DEGUMMING THE SILK FIBROIN.

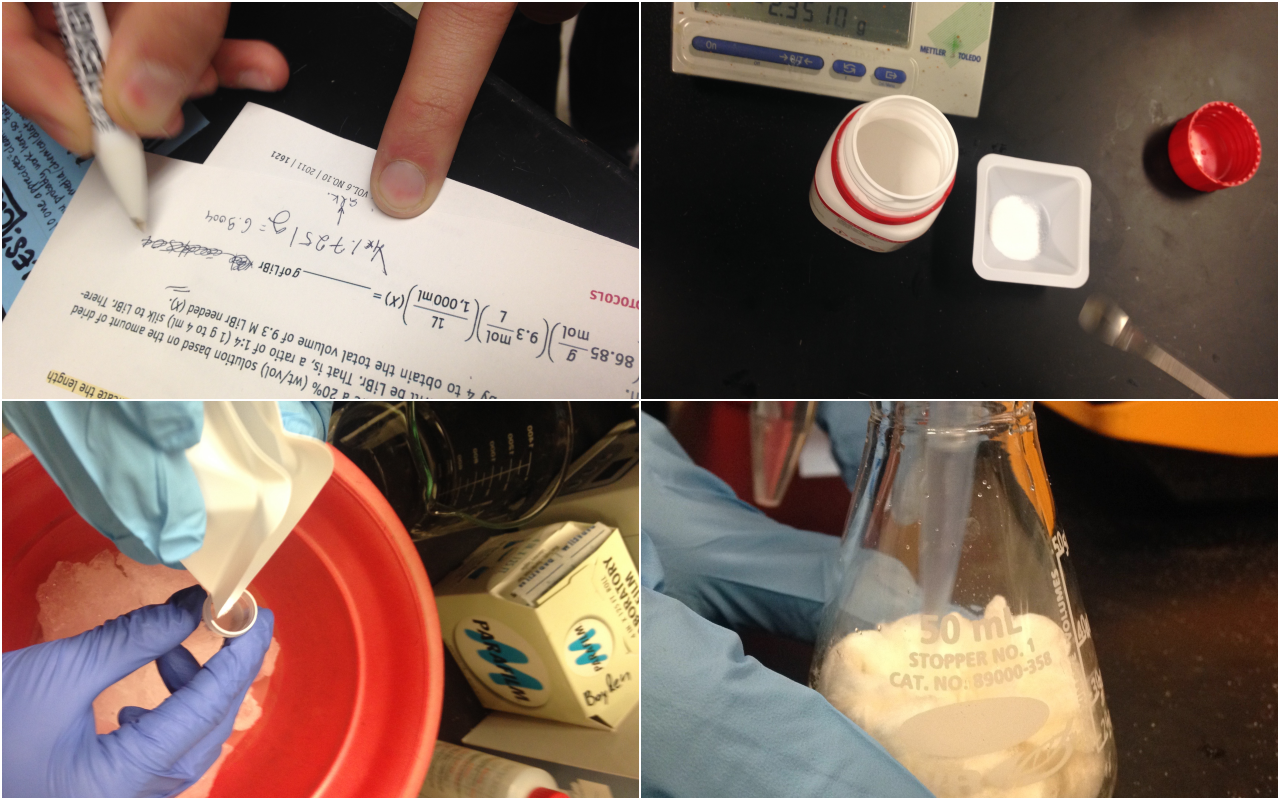

LITHIUM BROMIDE

https://www.sigmaaldrich.com/catalog/product/sial/213225?lang=en®ion=US

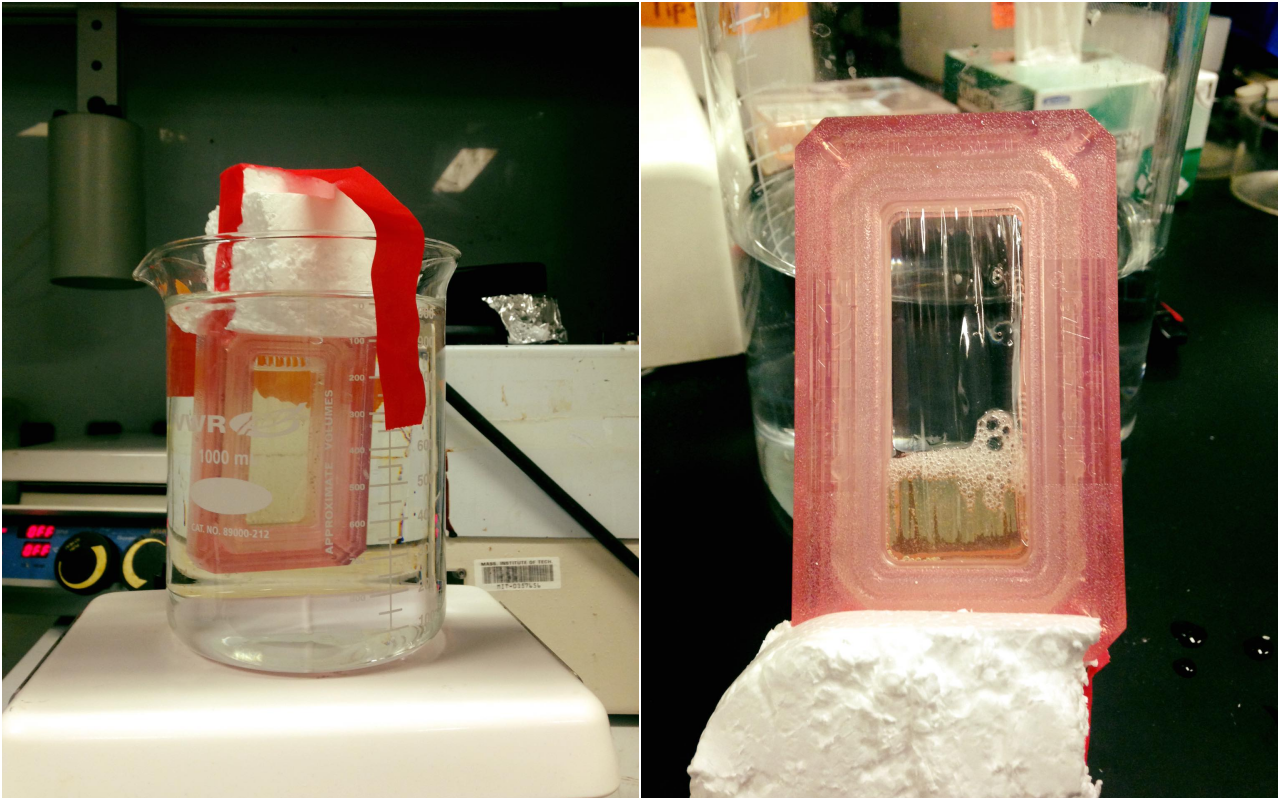

PUT THE REACTION ON ICE BECAUSE IT IS HIGHLY EXOTHERMIC!

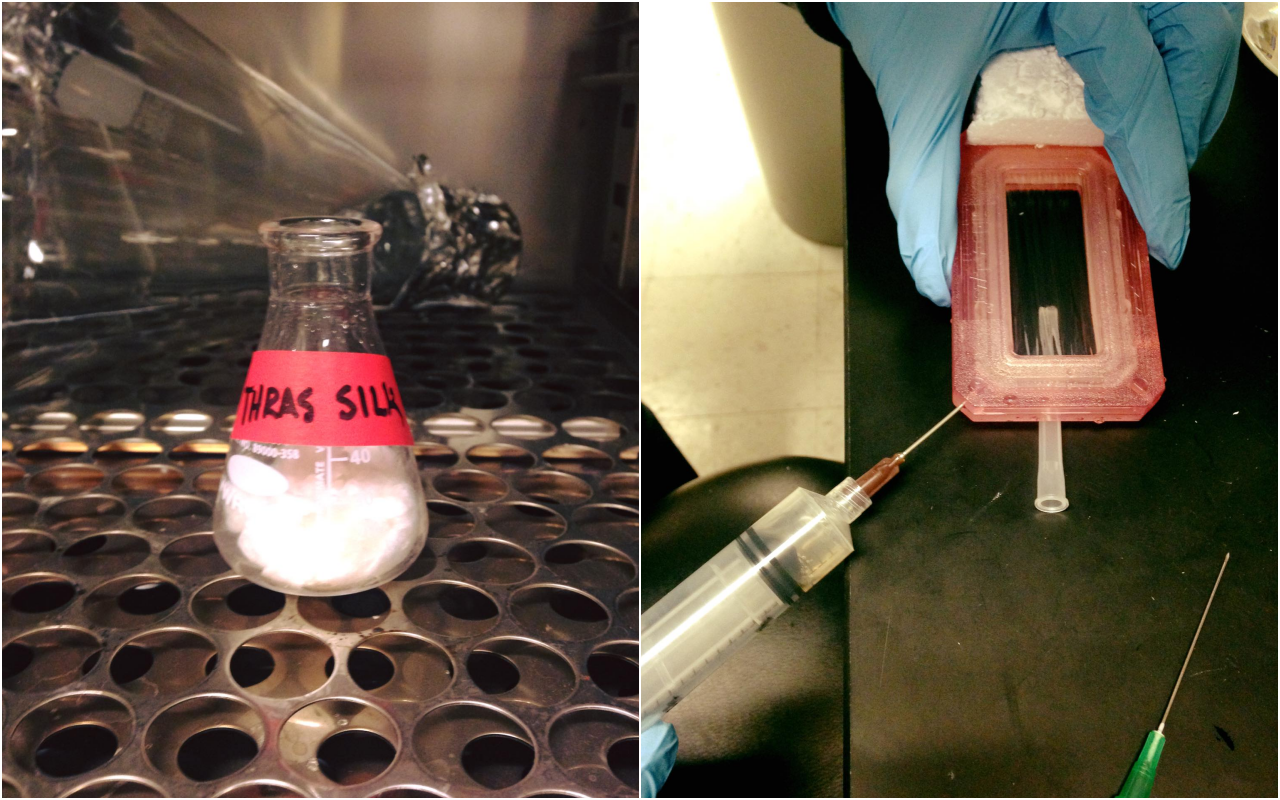

LET LiBr DISSOLVE SILK IN INCUBATION FOR 4 HOURS. THEN YOU CAN ADD SILK/LiBR to DIALYSIS CASSETTE (NOTE*** YOU SHOULD POUR THE SILK SOLUTION INTO THE TOP OF SYRINGE RATHER THAN SUCKING IT UP)

DIALYZE AGAINST ULTRAPURE WATER FOR 48 HOURS, THEN REMOVE SILK FROM CASSETTE. (NOTE*** IT IS MUCH EASIER TO POLE A HOLE IN TH CASSETTE AND THEN POUR INTO THE STORAGE TUBE RATHER THAN TRYING TO SUCK IT OUT WITH SYRINGE)

2. Fabrication of an edible, implantable, biodegradable diffraction grating through soft lithography (please, refer to Step 25H in Rockwood et al. Nature Protocols, 6, 1612–1631 (2011) in background reading

3. Superfab Assignment - Biomanufacturing in 3D Using the silk suspension obtained in Assignment #1 in combination with a XYZ dispensing system for the 3D printing of silk fibroin